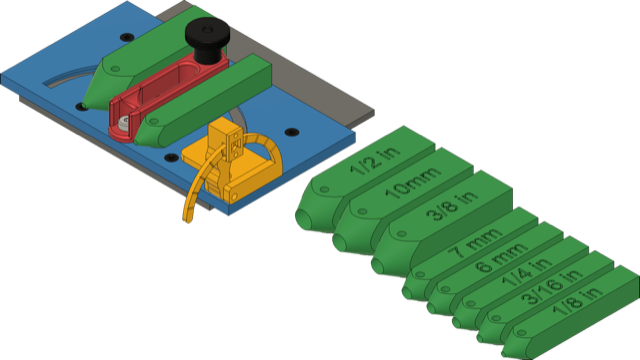

Sharpening Supplies has just announced an amazing new product: Sharp-Nado Sharpening Station.

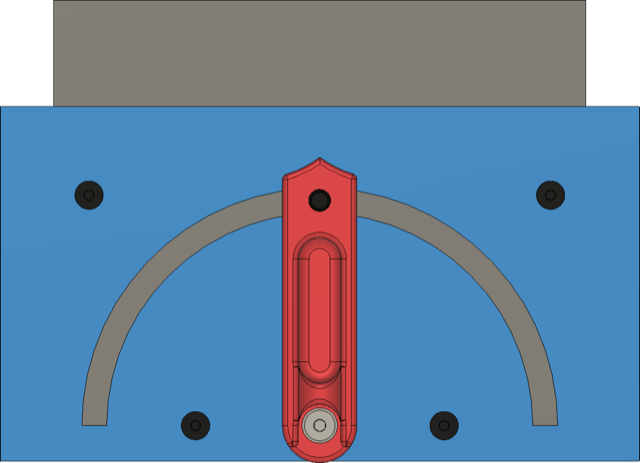

There is even room in the middle for your Bess tester!

Here's a link to the product announcement. I'm not sure when they will be shipping it.

There is even room in the middle for your Bess tester!

Here's a link to the product announcement. I'm not sure when they will be shipping it.