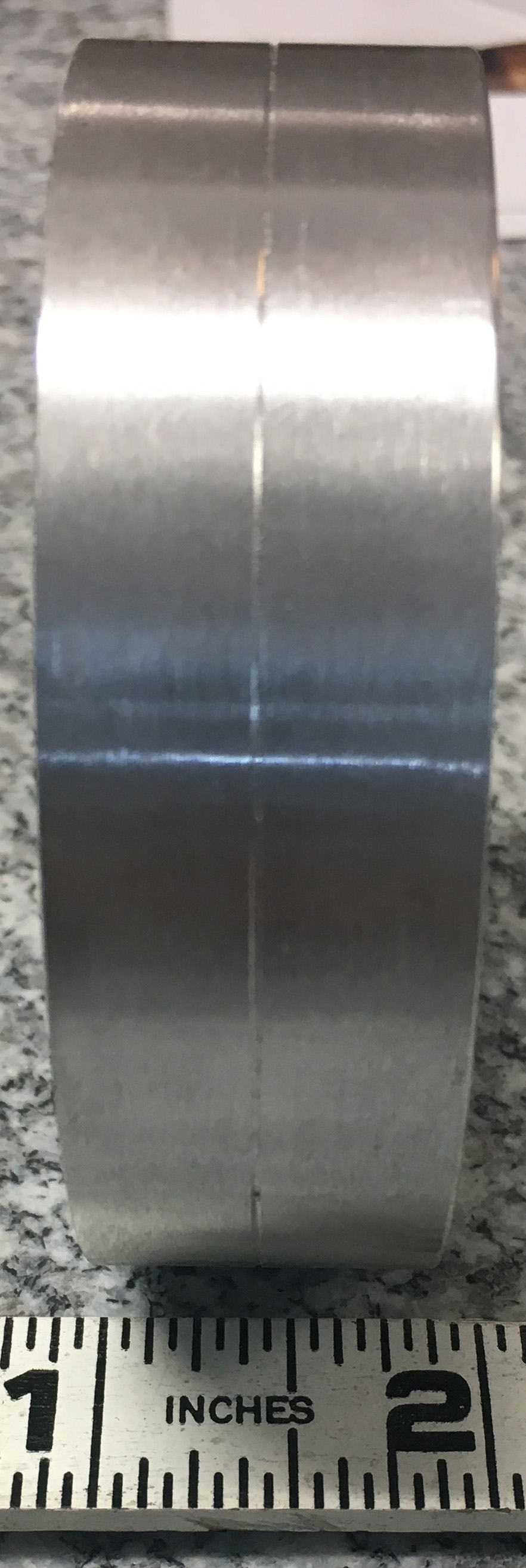

Wootz recommends the use of collars (see also, https://forum.tormek.com/index.php?topic=3050.msg16671#msg16671 ).

I just keep them on the jigs.

Kind regards,

Rich

I just keep them on the jigs.

Kind regards,

Rich

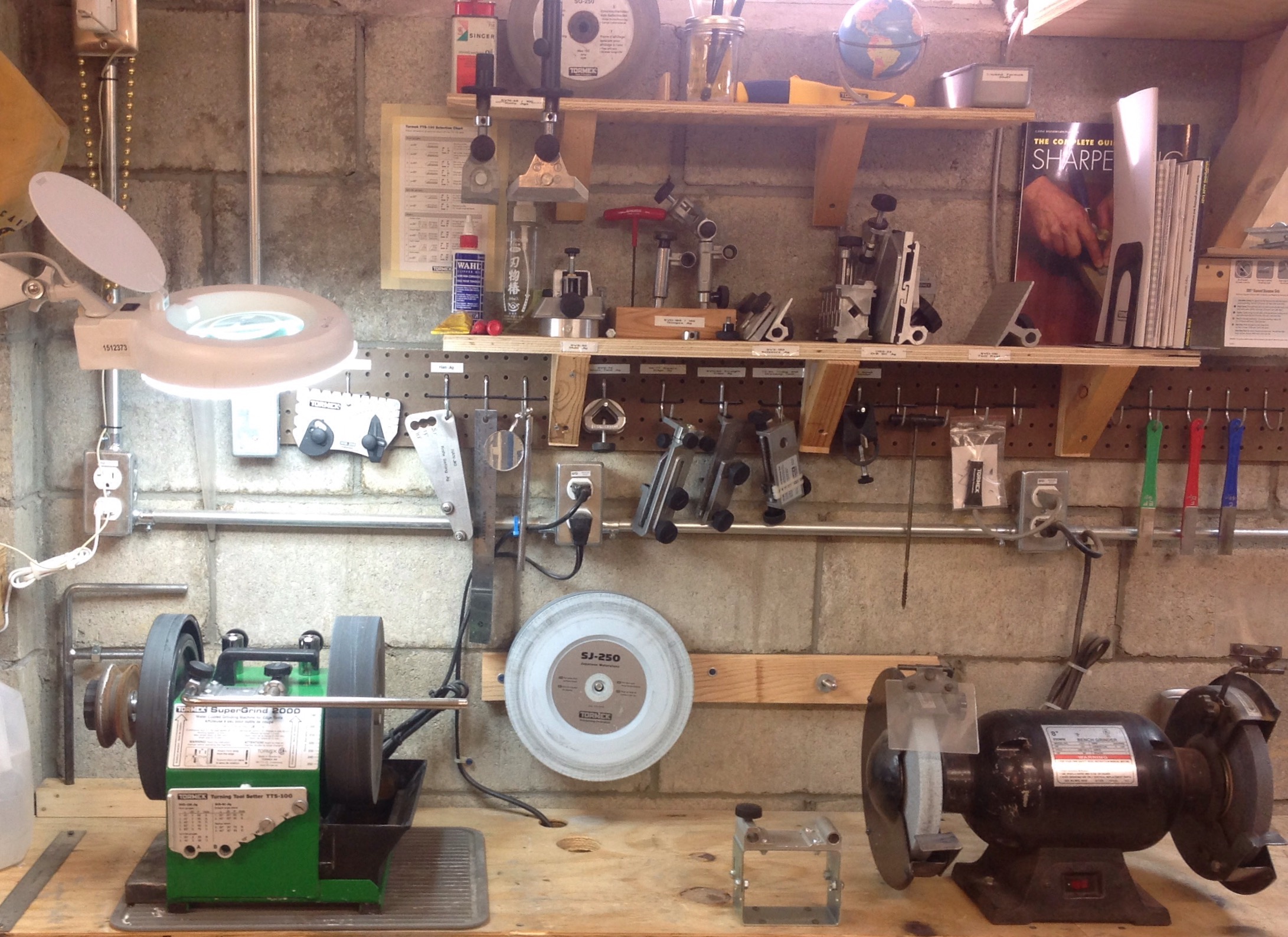

Welcome to the Tormek Community. If you previously registered for the discussion board but had not made any posts, your membership may have been purged. Secure your membership in this community by joining in the conversations.

www.tormek.com

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Show posts MenuQuote from: Kavik on August 07, 2017, 02:33:16 AM

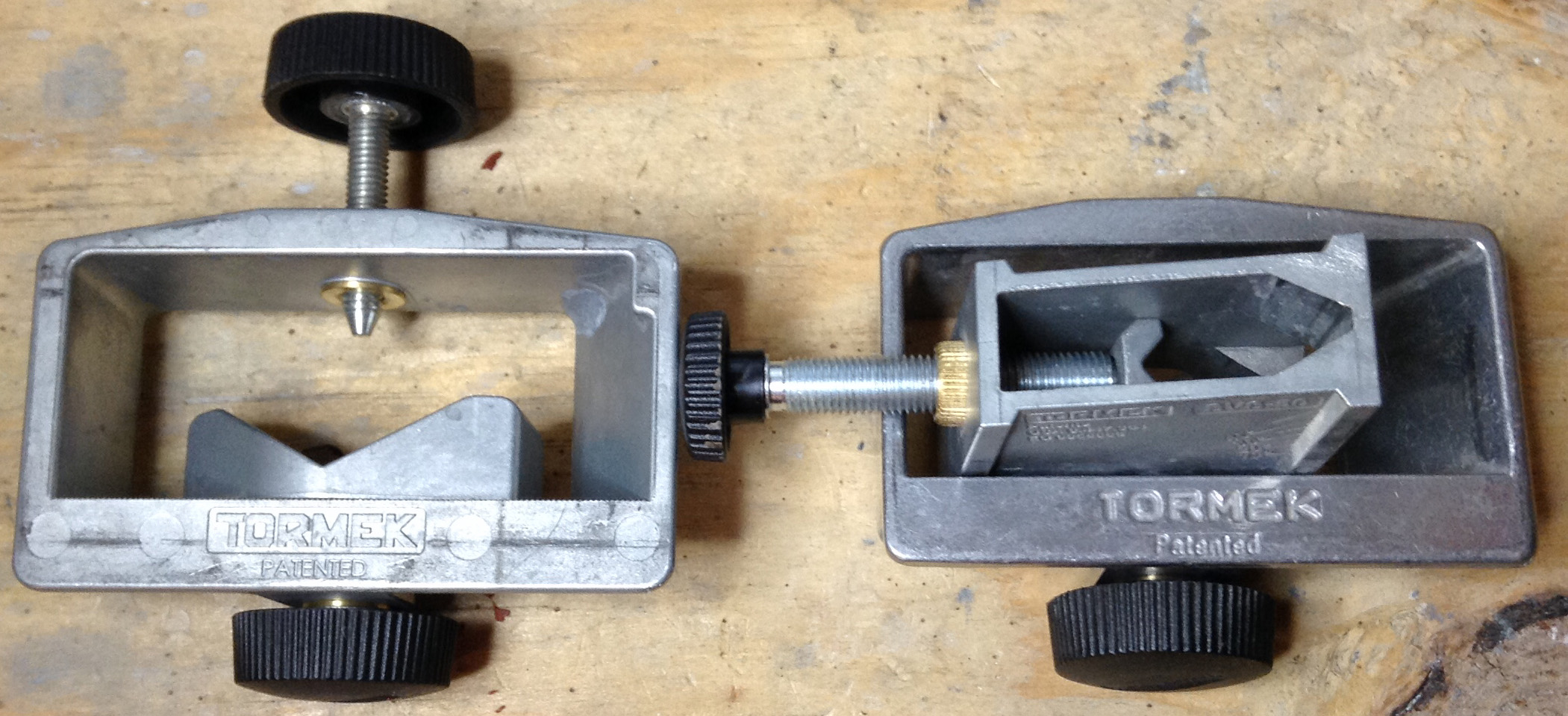

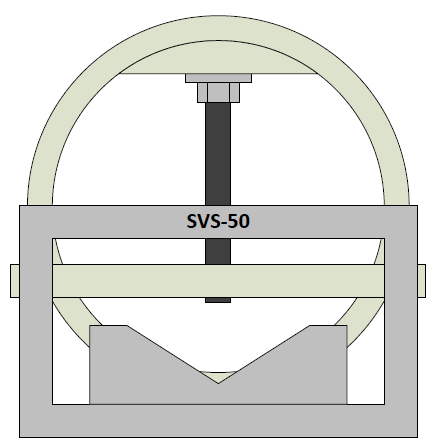

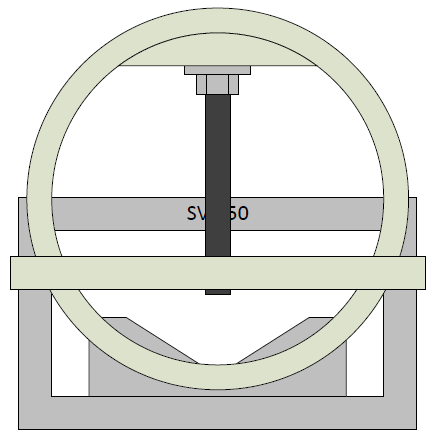

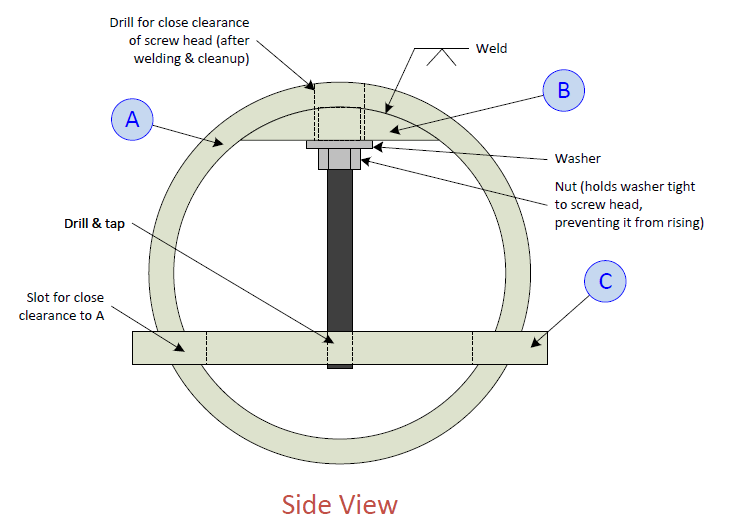

Very interesting concept, sort of a hybrid of the svs-50 and the svs-32

2 thoughts, if you don't mind some input:

1) it looks like your screw is off centered on the D collar, as well as slightly angled. That could be causing the twist. For your next attempt, maybe it'd be easier to drill that hole before attaching to the half circle?

2) I think the most ideal solution would be to have the collar attached to the jig, rather than the tool. Then there's no need to set up the spacing and fiddle with 2 separate bolts every time. I could see this with that same D shape attached to the jig with just a flat plate across the top of the two..... Of course, then you're dealing with joining zinc and aluminum, but i see no reason you couldn't drill and tap instead of weld for that part

Just some thoughts to consider, but this idea in general is really cool. Two thumbs up for your innovation

Quote from: Jan on August 08, 2017, 06:10:46 PMI was pleased to see the TTS setter modified for knives among your jigs.

Quote from: Kavik on August 07, 2017, 03:38:18 PMIt's gonna take a bit more practice combining the motion of rotating the jig while at the same time keeping the tool moving across the surface to keep from wearing grooves

Page created in 0.013 seconds with 15 queries.