Ken inspired me to think about the usage of TTS-100 for setting the edge angle of a tool mounted in the square edge jig SE-76. The results of my research shows that it is well possible.

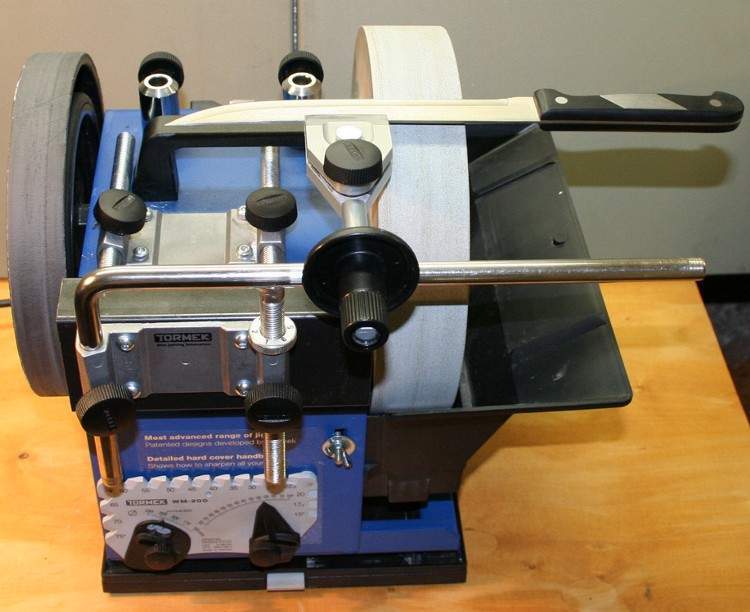

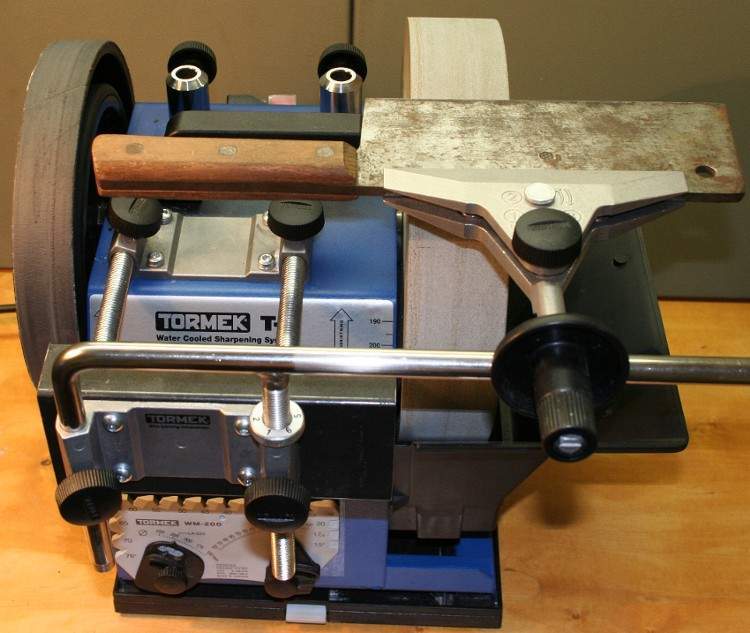

First, mount the tool in the square edge jig with the protrusion 44 mm (1.73").

Second, set the position of the US using the inner hole (B) of the TTS-100.

Third, these two steps ensure the edge angle aproximately 25 degrees.

I have checked the edge angle setting with the angle master. I have got 25.5 degrees.

This setting should almost not depend on the grindstone diameter.

Jan

First, mount the tool in the square edge jig with the protrusion 44 mm (1.73").

Second, set the position of the US using the inner hole (B) of the TTS-100.

Third, these two steps ensure the edge angle aproximately 25 degrees.

I have checked the edge angle setting with the angle master. I have got 25.5 degrees.

This setting should almost not depend on the grindstone diameter.

Jan