Quote from: tgbto on April 10, 2022, 05:36:40 PM

Still, I am not sure why one would prefer taking three measurements (both measurements shown here plus the one at sharpening time) compared to only one from USB to top of wheel...

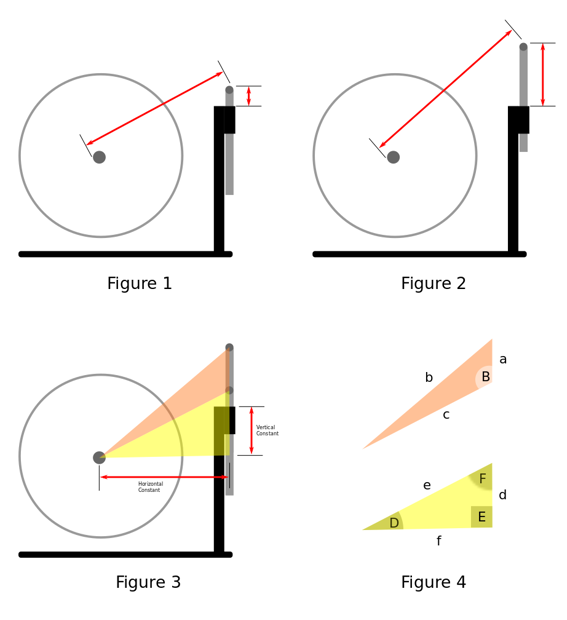

tgbto, the measurements described are performed just once and the constants are stored as configuration settings in the calculators that require them.

Quote from: Ken S on April 10, 2022, 10:14:20 PM

I do not understand "notoriously difficult to measure, even for the most skilled".

Ken, with respect you misread my first sentence "The horizontal and vertical constants used by various calculators to determine the support bar height from a given origin, such as the machine cover or support bar sleeve, are notoriously difficult to measure physically, even for the most skilled."

Andrew