Quote from: Ken S on June 10, 2016, 04:31:30 AM

ps We must credit Dutchman and Jan as part of the design team.

Great minds creating great ideas. Thanks.

In order to find the "right"/ former angle I always use a marker. But there is no always a distinct angle to find so I use my experience. After so many knifes I know the approximate installation of the knives considering thickness, width, length, and angle needed/ asked.

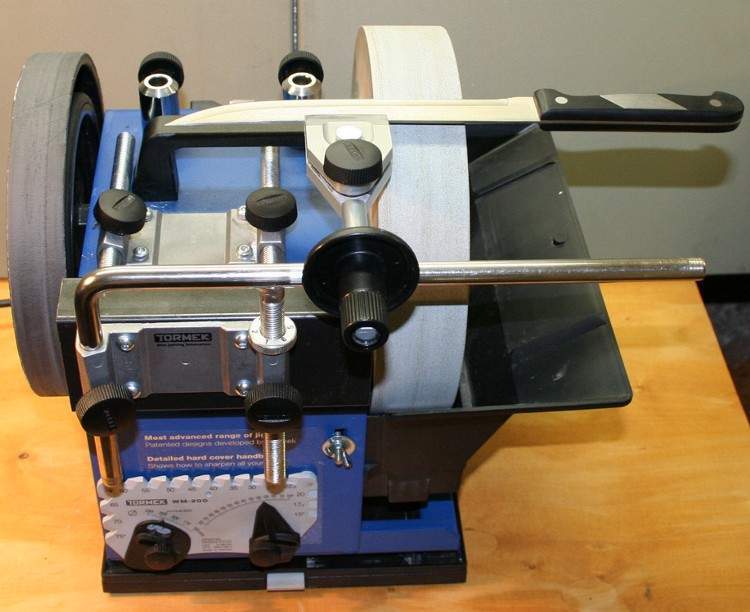

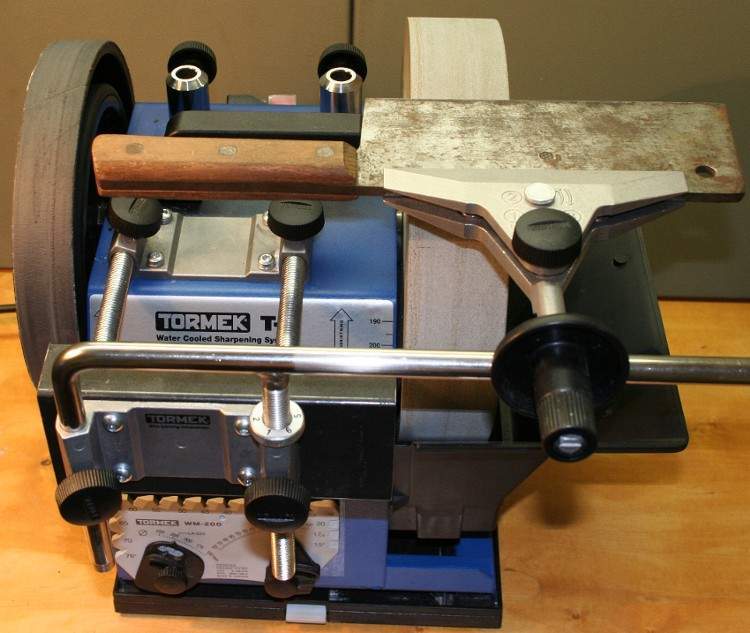

Another tip is: I try to fasten the knife at the jig with same length from jig base to curved part of blade tip as the blade end from the jig base. Then I follow the knife curve when sharpening which gives me as close angle as possible trough the hole sharpening process, following an imaginary line on the stone. Little lifting of the tip is always required of course.

)

)