Hi KSMike and Ken,

I really appreciate you guys taking the time to post back and help me with this problem.

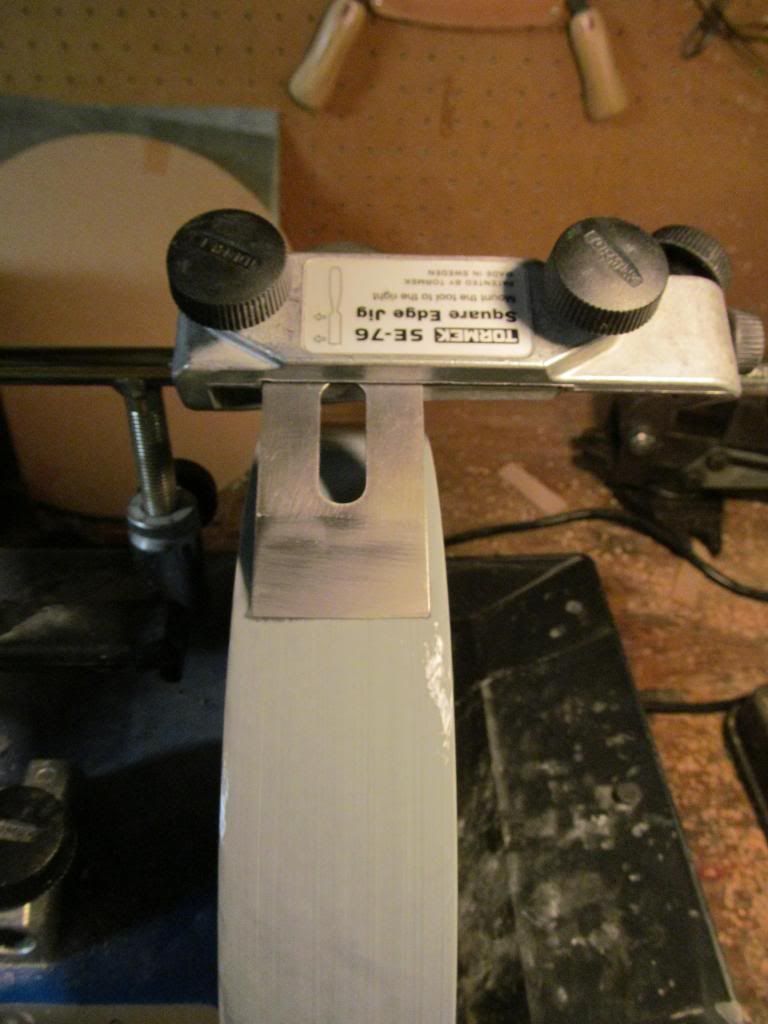

To answer KSMike, I think the bar is bent sloping downwards. So the part where it's held by the Tormek is high, and the part where it ends, is low. I understand what you mean by the bar truing the stone exactly, even if there's a slope to it. Although, I wonder, what if the slope isn't exactly straight? What if it starts high, goes low, and then comes up high again? Not sure if that would cause a problem.

What if it starts high, goes low, and then comes up high again? Not sure if that would cause a problem.

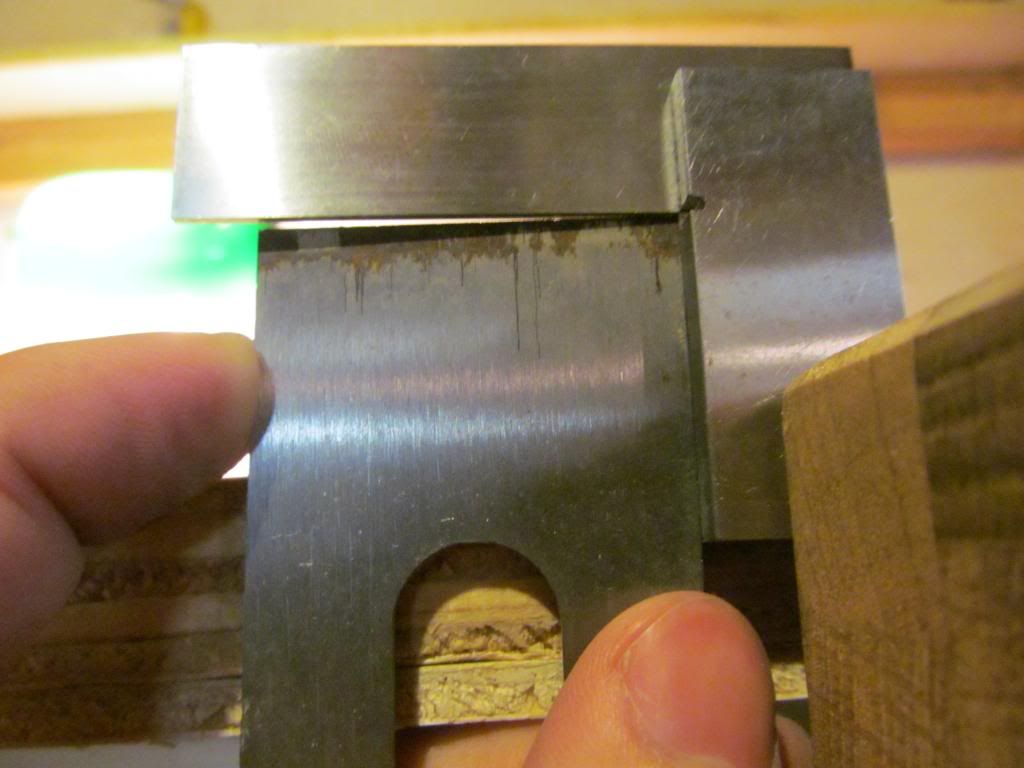

Concerning the jig, I was wondering about that myself, actually. The problem with the jig is that I have to trust the the edge of the jig is at a perfect right angle, because the way that it works is that you just push the blade up against the wall of the jig, and that's that. There's no adjustment for the jig wall or anything, So what you've got, is what you got. I make sure that it is snug up against the wall, but that's really all I can do. I mean, honestly, the problem could be with the jig itself. Maybe the wall is not straight.

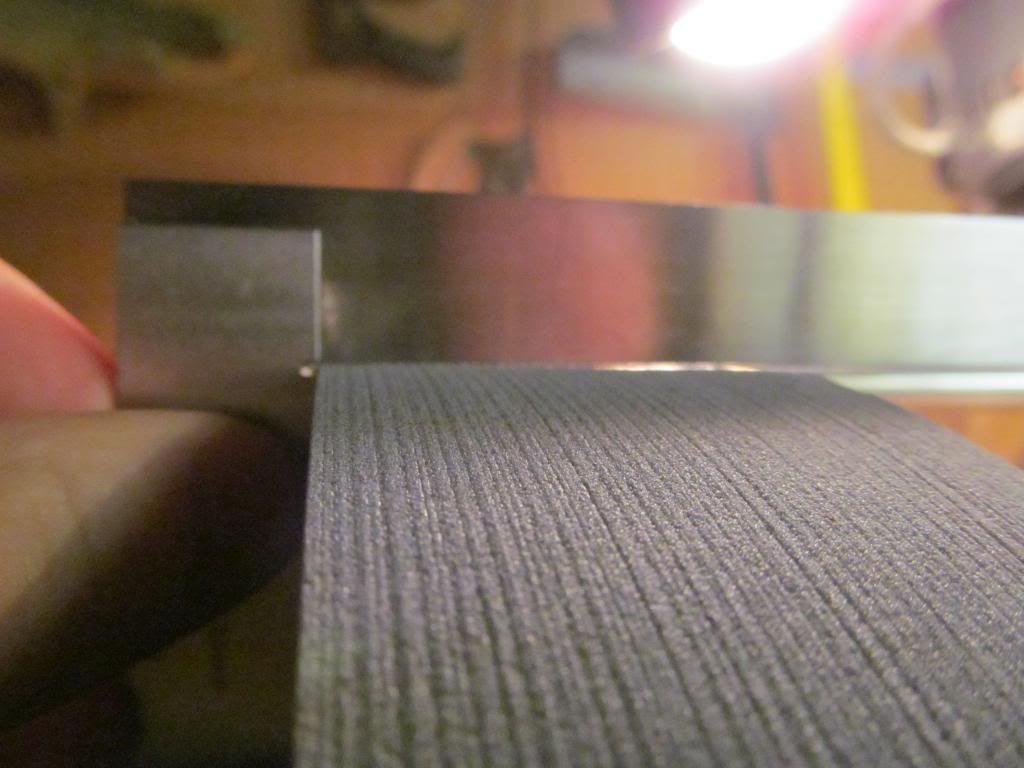

The picture that you post is very good. Thanks for posting it. If I was acheiving results like this, it would not be a problem at all for me. It looks like you're high on the side and low in the middle. I could true that up with a couple swipes on the Japanese water stone and have a perfect blade edge, no problem. I don't know how you are acheiving that edge on this machine. Mine doesn't work like that.

To answer Ken, I am planing the most difficult and most challenging thing that one could plane (as far as I know of at least), which is violin ribs. They are extremely difficult to plane because the blade likes to bite into the flames of the maple and take out huge chunks. If everything is not exactly precise, your work will be ruined.

Yes, I agree with lateral adjustments. I definitely adjust it laterally with a small hammer. However, with the precise nature of the work that I am doing, it's only acceptable to adjust the plane a fraction of a hair, because the plane blade needs to be fully supported by the mouth. If it is not, it will bite into the flames. If I was planing some other type of wood, I would be made in the shade. I can plane poplar all day with a sub-par plane, but ribs are a different animal.

So I'm not sure what I will need to do. May have to sell it, which would be unfortunate, because I probably will only get half of my original investment back. Need to think it through.

But thanks for your responses. I really appreciate the help on this forum!!

I really appreciate you guys taking the time to post back and help me with this problem.

To answer KSMike, I think the bar is bent sloping downwards. So the part where it's held by the Tormek is high, and the part where it ends, is low. I understand what you mean by the bar truing the stone exactly, even if there's a slope to it. Although, I wonder, what if the slope isn't exactly straight?

What if it starts high, goes low, and then comes up high again? Not sure if that would cause a problem.

What if it starts high, goes low, and then comes up high again? Not sure if that would cause a problem. Concerning the jig, I was wondering about that myself, actually. The problem with the jig is that I have to trust the the edge of the jig is at a perfect right angle, because the way that it works is that you just push the blade up against the wall of the jig, and that's that. There's no adjustment for the jig wall or anything, So what you've got, is what you got. I make sure that it is snug up against the wall, but that's really all I can do. I mean, honestly, the problem could be with the jig itself. Maybe the wall is not straight.

The picture that you post is very good. Thanks for posting it. If I was acheiving results like this, it would not be a problem at all for me. It looks like you're high on the side and low in the middle. I could true that up with a couple swipes on the Japanese water stone and have a perfect blade edge, no problem. I don't know how you are acheiving that edge on this machine. Mine doesn't work like that.

To answer Ken, I am planing the most difficult and most challenging thing that one could plane (as far as I know of at least), which is violin ribs. They are extremely difficult to plane because the blade likes to bite into the flames of the maple and take out huge chunks. If everything is not exactly precise, your work will be ruined.

Yes, I agree with lateral adjustments. I definitely adjust it laterally with a small hammer. However, with the precise nature of the work that I am doing, it's only acceptable to adjust the plane a fraction of a hair, because the plane blade needs to be fully supported by the mouth. If it is not, it will bite into the flames. If I was planing some other type of wood, I would be made in the shade. I can plane poplar all day with a sub-par plane, but ribs are a different animal.

So I'm not sure what I will need to do. May have to sell it, which would be unfortunate, because I probably will only get half of my original investment back. Need to think it through.

But thanks for your responses. I really appreciate the help on this forum!!