Please share the STL files.

- Welcome to Tormek Community Forum.

News:

Welcome to the Tormek Community. If you previously registered for the discussion board but had not made any posts, your membership may have been purged. Secure your membership in this community by joining in the conversations.

www.tormek.com

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

#2

General Tormek Questions / Re: US-103 & US-105 difference?

Today at 09:24:47 PM

Both have legs which are 145mm long. The difference is in the top bar

As noted, the US-103 is 10mm shorter to accommodate the 200mm grindstone which is 10mm thinner than the 250mm grindstone.

- US-105 = 305mm

- US-103 = 295mm

As noted, the US-103 is 10mm shorter to accommodate the 200mm grindstone which is 10mm thinner than the 250mm grindstone.

#3

General Tormek Questions / Goniostat for the Tormek

Today at 09:15:47 PM

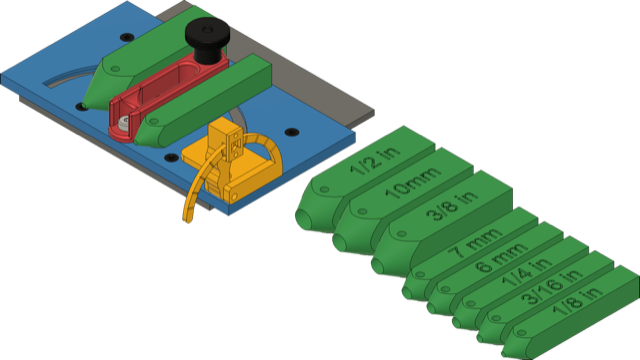

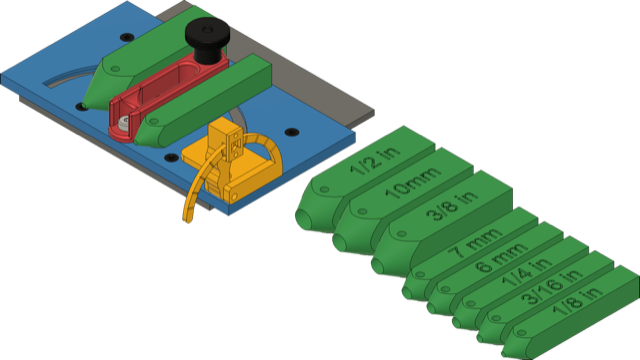

I am in the process of designing a goniostat for the Tormek, and am seeking feedback. This jig is designed for sharpening these types of tools:

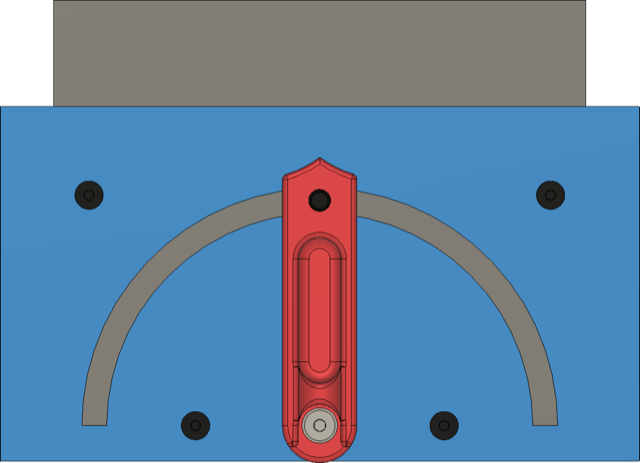

The picture below shows the parts I've designed so far.

The parts are:

The parts are:

- Single point cutting tools for small metal lathes.

- Engraving bits used in rotary cutters, especially as driven by a router type motor on a CNC machine, and

- Tools for ornamental turning, especially on rose engines.

- End mills

The picture below shows the parts I've designed so far.

- DBS-22 Plate (item #2, p/n 2350, shown in gray). This slides left / right on the base of the DBS-22.

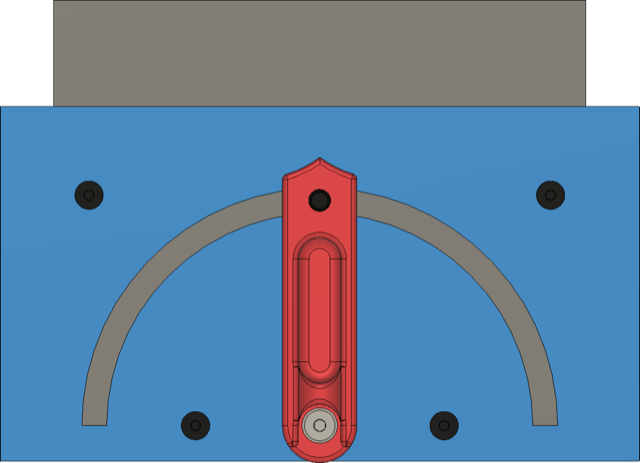

- Goniostat Base Plate (blue). The final one will need some form of marking to show the angle for setting. The drawing below shows shows the tool fence with the pointer at the top and the locking knob removed. This angle would read 90°, and the fence can be rotated left or right as needed.

- Tool Fence (red) - used to set the angle for grinding the edge. The tool or tool holder would be held against this when sharpening.

The bolt coming up thru the Goniostat Base Plate is a T-Slot bolt from McMaster-Carr (p/n 92770A113). I had to turn the shoulder down a little so that it did not protrude too much above the surface of the Goniostat Base Plate. The area noted in red below is what was turned to the the same as the screw shaft.

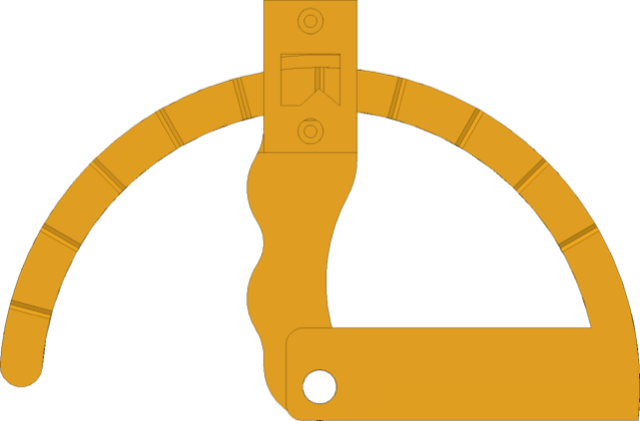

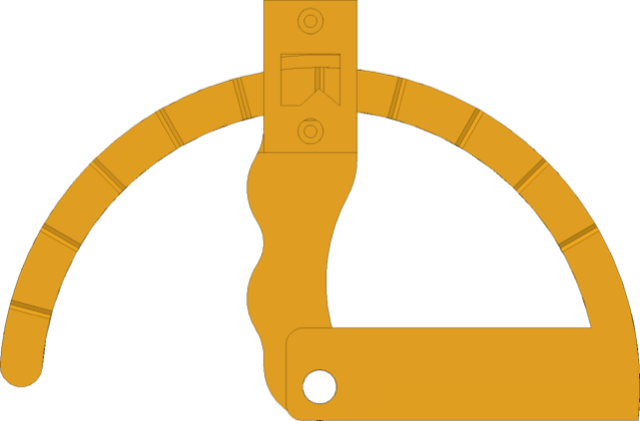

- Plate Angle Gauge (yellow) - used to set the angle of the plate (DBS-22 and Goniostat Base Plate) on the USB. This would also have indicator marks. They are simulated at 15° increments in the drawing below. There are no rollers on the design (like on the TTS-100). That would be an improvement which would be welcome.

- Round Tool Holders (green) - these are used to hold tools for sharpening which have round shafts. They have a 60° nose angle to allow the held tool to be ground up close. The hole in the top is for a 6mm set screw to hold the tool's shaft in place.

- The sizes shown on the right are the ones I will use. 3D printing the 8 of them will take a while on my 3D printer, which is pretty slow. There are two generic ones shown on the left. The left-most one is 25mm square and would be drilled for holding bigger tools. The other one is 15mm square and would be drilled for holding smaller tools.

#4

Wood Carving / Re: Japanese chisel challenge

May 21, 2024, 04:36:48 AM

The MB-102 helps greatly and allows you to use the side of the grindstone.

#5

General Tormek Questions / Re: SG-250 clogging / cleaning

May 18, 2024, 02:27:50 AM

The SB-250 was designed for harder steels. You might want to get one of those if you're going to be sharpening such metals often.

#6

Drill Bit Sharpening / Re: Non-Tormek "Micro" Drill Bit Grinder

May 11, 2024, 09:01:48 PM

Those tools are really cool! Thanks for sharing.

#7

General Tormek Questions / Re: Manual

May 07, 2024, 02:15:50 AM

Kevin, after you get through the excellent Tormek manual, the other books of note are catalogued here: https://sharpeninghandbook.info/indexBooksVideosWebSites.html.

#8

General Tormek Questions / Re: Newbie here....

May 07, 2024, 02:11:45 AM

The Tormek Sharpening Class videos cataloged here are excellent: https://sharpeninghandbook.info/indexBooksVideosWebSites.html

#9

General Tormek Questions / Re: New user; Japanese waterstone wheel

May 07, 2024, 02:05:47 AMQuote from: MerryMadMick on May 05, 2024, 11:48:37 PMHello,

I recently purchased a T-8 and after sharpening a few of my plane irons and chisels I discovered that I was obviously terrible at sharpening by hand. Considering the number of new bandages on my finger tips, the Tormek works well.

I suffer from the condition known as Gear Acquisition Syndrome, which I'm sure many of you have experienced. The outward manifestation of this condition is wondering how to make something that works exceedingly well even better. To that end, will the Japanese water stone allow me to produce an edge that will perform fission on a hydrogen atom?

I joke only slightly, but is the edge produced by the Japanese stone even more terrifyingly sharp than the what can be made by the graded stock wheel and strop?

Thank you.

As you mentioned sharpening chisels, I recommend you read thru this thread: https://forum.tormek.com/index.php/topic,4971.msg35710.html#msg35710. The overriding idea I started the thread with is that I wanted to get pretty darn sharp, and resharpen often in a speedy manner.

If you buy into that approach, then the TTS-100 is a great add-on, along with the 3D printed jig outlined here: https://sharpeninghandbook.info/indexJigs.html#ProjJigTTS100.

I take that approach, using the SG grindstone, and find it works wonderfully. My edges are certainly not as sharp as they would be if I used a 13,000 grit stone, but I find that the cutting edges work well for me.

Good luck,

Rich

P.S., I have all 6 grindstones (SG, SB, SJ, & the 3 diamond stones), yet I find with woodworking bench tools that the SG grindstone is easiest to use.

#10

General Tormek Questions / Re: Left handed stone

April 16, 2024, 03:21:42 PMQuote from: John Hancock Sr on April 16, 2024, 12:47:09 AMPlease post picsQuote from: RichColvin on April 02, 2024, 04:35:10 AMThis is still my favorite: the Tormek T-99

When you see Japanese knife sharpeners on their huge waterstones that does not seem so absurd. Also grandpa's huge sharpening wheel. We actually have one here. I intend to build a new frame for it.

#11

General Tormek Questions / Re: Marking chisels for initial insertion into jig

April 03, 2024, 01:56:08 PM

Yeah, marks on plywood would work well too. The projections needed are discussed in this forum thread: https://forum.tormek.com/index.php/topic,4971.msg35710.html#msg35710

#12

General Tormek Questions / Re: Tool Marking

April 03, 2024, 01:52:47 PMQuote from: tgbto on April 02, 2024, 11:55:47 AMHey everyone,What laser do you use?

I thought I'd share with you my findinds pertaining to laser engraving. I started with a 5W output 455 nm, and I managed to get sub-par results by coating the blade beforehand (sharpie, mustard, painter's tape...).

I recently acquired a USD 400ish 2W 1064nm IR head, and the results are amazing. I can engrave knife blades with the sharpening angle or with their owner's name. I can also put a straight mark on a chisel right where I want. It can also mark plastics (preferably light or dark as the result is kind of greyish), so

handles can be marked too.

It might be a nice addition to a premium sharpener's toolset. Mine is an open-frame one, so quite bulky, but there are also portable versions that will engrave up to 70x70 mm.

Cheers,

Nick.

#13

General Tormek Questions / Re: Left handed stone

April 02, 2024, 04:35:10 AM

This is still my favorite: the Tormek T-99 https://www.sharpeningsupplies.com/New-Tormek-T-99-W213.aspx

#14

General Tormek Questions / Re: Marking chisels for initial insertion into jig

April 02, 2024, 04:31:56 AM

The 3D-printed jig I outlined works the same way your board does for setting the protrusion of the chisel beyond the SE-77 jig. And, as Ken noted, the TTS-100 is used to set the USB distance to the stone to a standard.

This approach handles 3 angles: 20°, 25°, & 30°. I think those work well for the majority of chisels.

This approach handles 3 angles: 20°, 25°, & 30°. I think those work well for the majority of chisels.

#15

Drill Bit Sharpening / Re: Do No Use Drill Bit Jig (DBS-22) on Grinders That Throw Grit Downward

April 02, 2024, 04:26:02 AM

I'm at the point where I have complete sets of Imperial, number and letter sizes, and metric bits. If I break a bit, it is usually one which I use often, so I replace it with a well-made one (and buy a 2d for a backup).