Well this has been a bit of a rollercoaster so far.

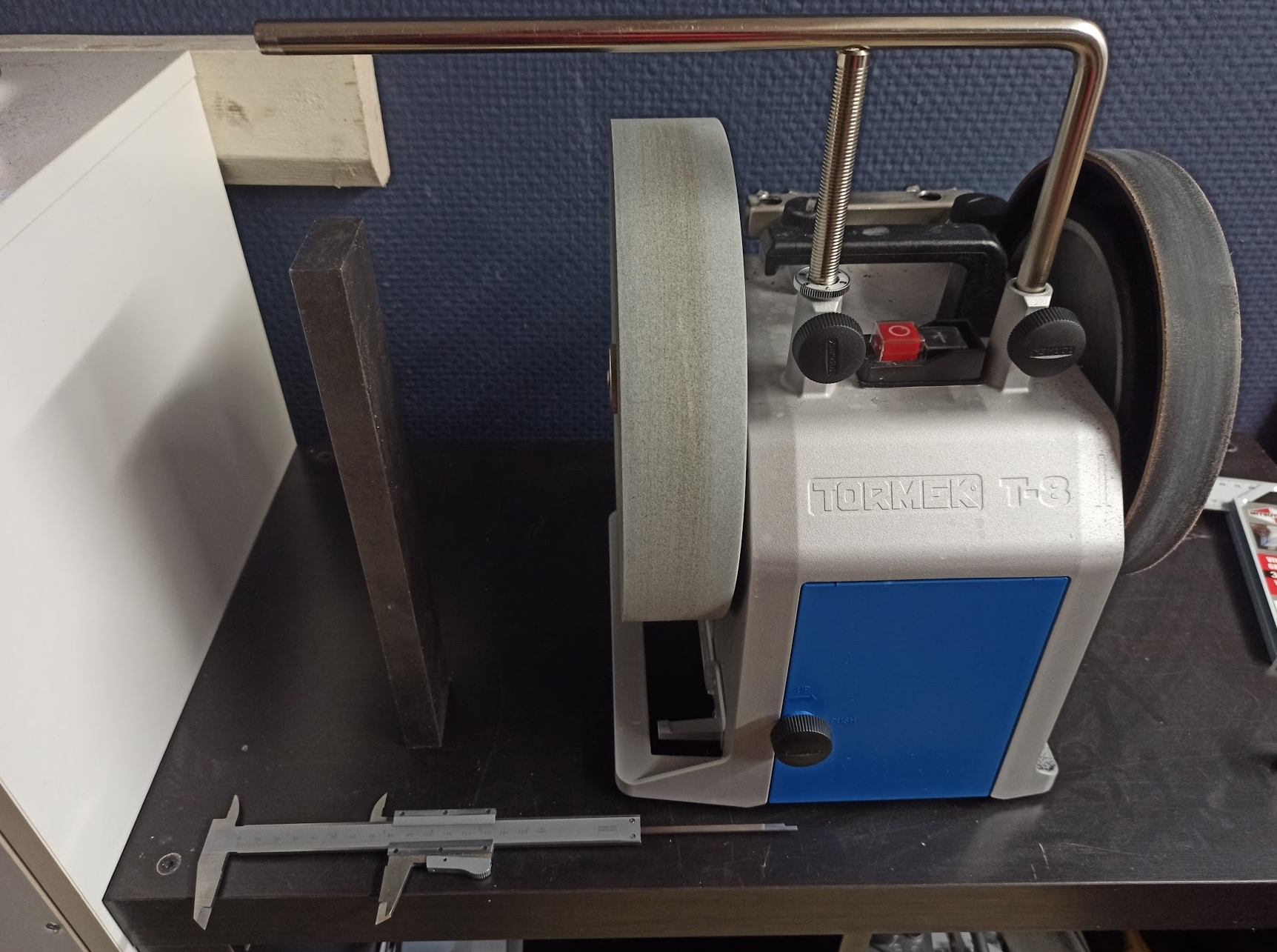

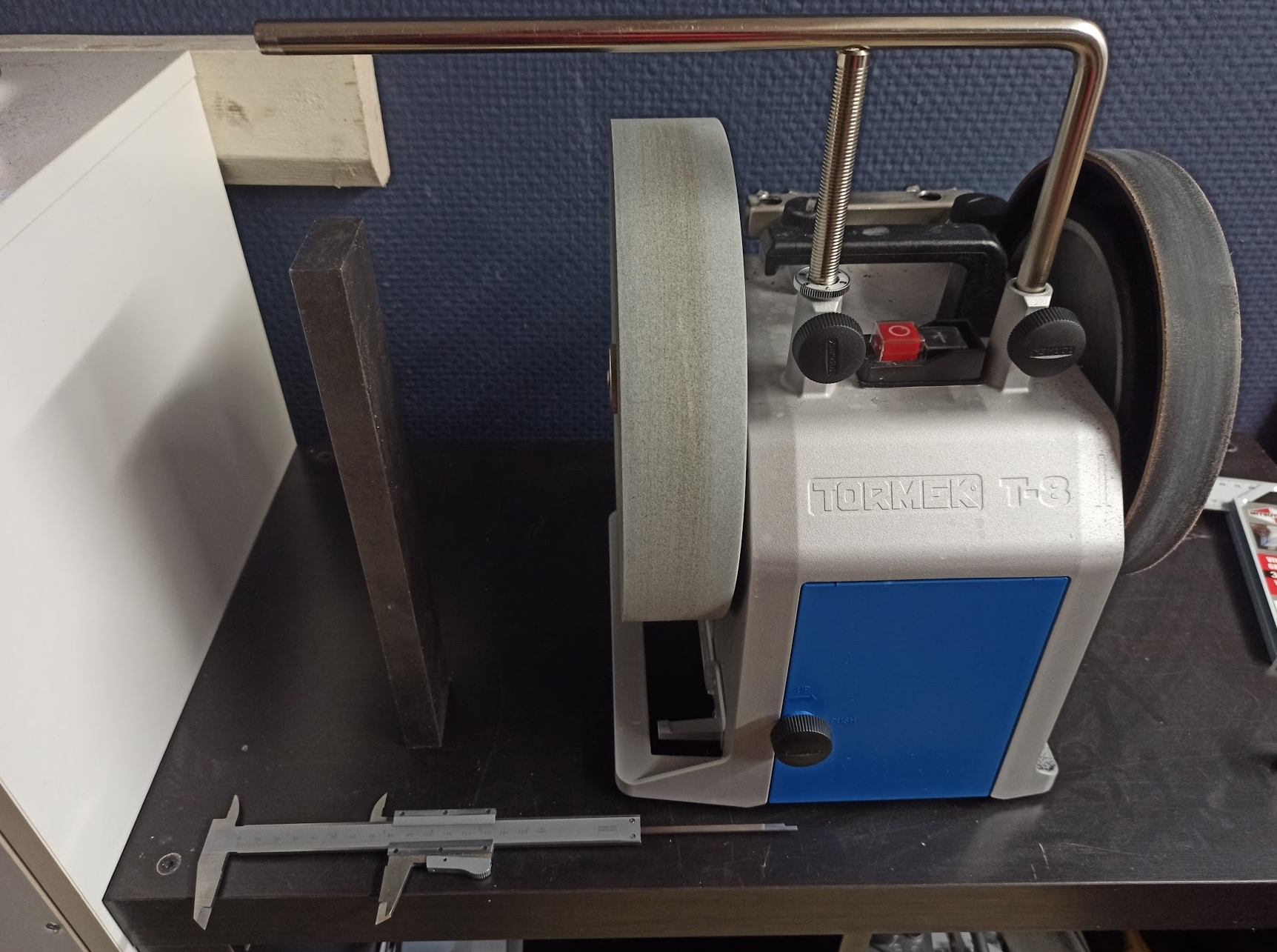

And yes, I did just move my machine to a more dedicated spot

I did some testing as suggested and my findings are somewhat surprising.

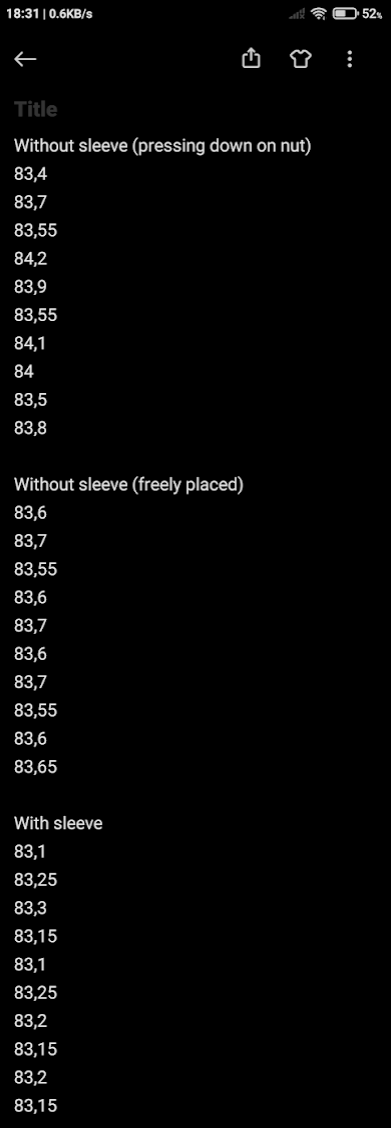

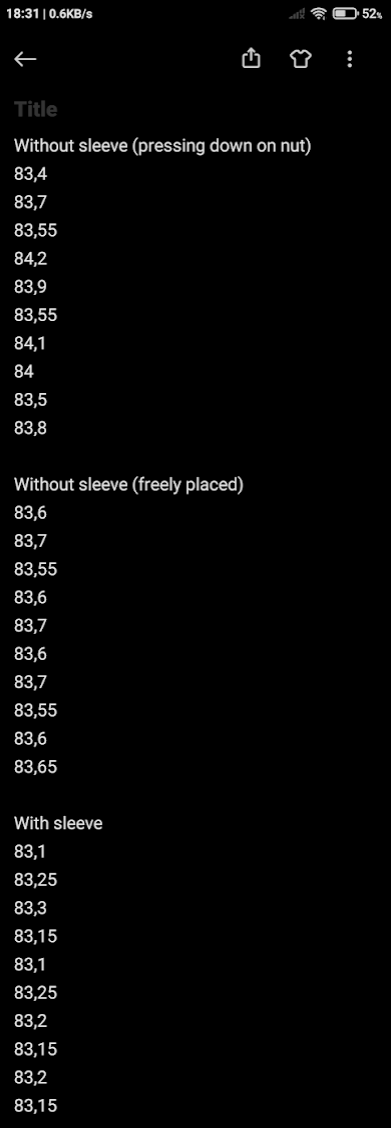

The measurements were taken from the top of the USB and down to the piece of solid bar steel. With both locking screws tightened.

- repeated test measurements with no altering of the USB, showed repeatability to within 0,05mm accuracy.

Results:

Pressing down on the threaded bar when locking it in, showed a max deviation of 0,8mm. (I didn't touch the nut, although I wrote it like that in my notes on my phone, it was done like in the Tormek manual/handbook)

Placing the USB freely before locking it in without touching it further, showed a max deviation of 0,15mm.

Using the sleeve and applying downwards pressure and spin to only the sleeve itself, while locking in the USB, showed a max deviation of 0,2mm.

I would say that 0,8mm deviation is too much for my liking, this corresponds with my observations truing the stone with the TT-50, where I noticed that from one pass to another, suddenly I would only be removing material from about half the stone, when taking away material in ½ increments of the micro adjust.

But I will also admit, that it isn't as bad as I thought it would be and I'm nowhere near experienced enough to really tell how much of an impact it might have on the final results.

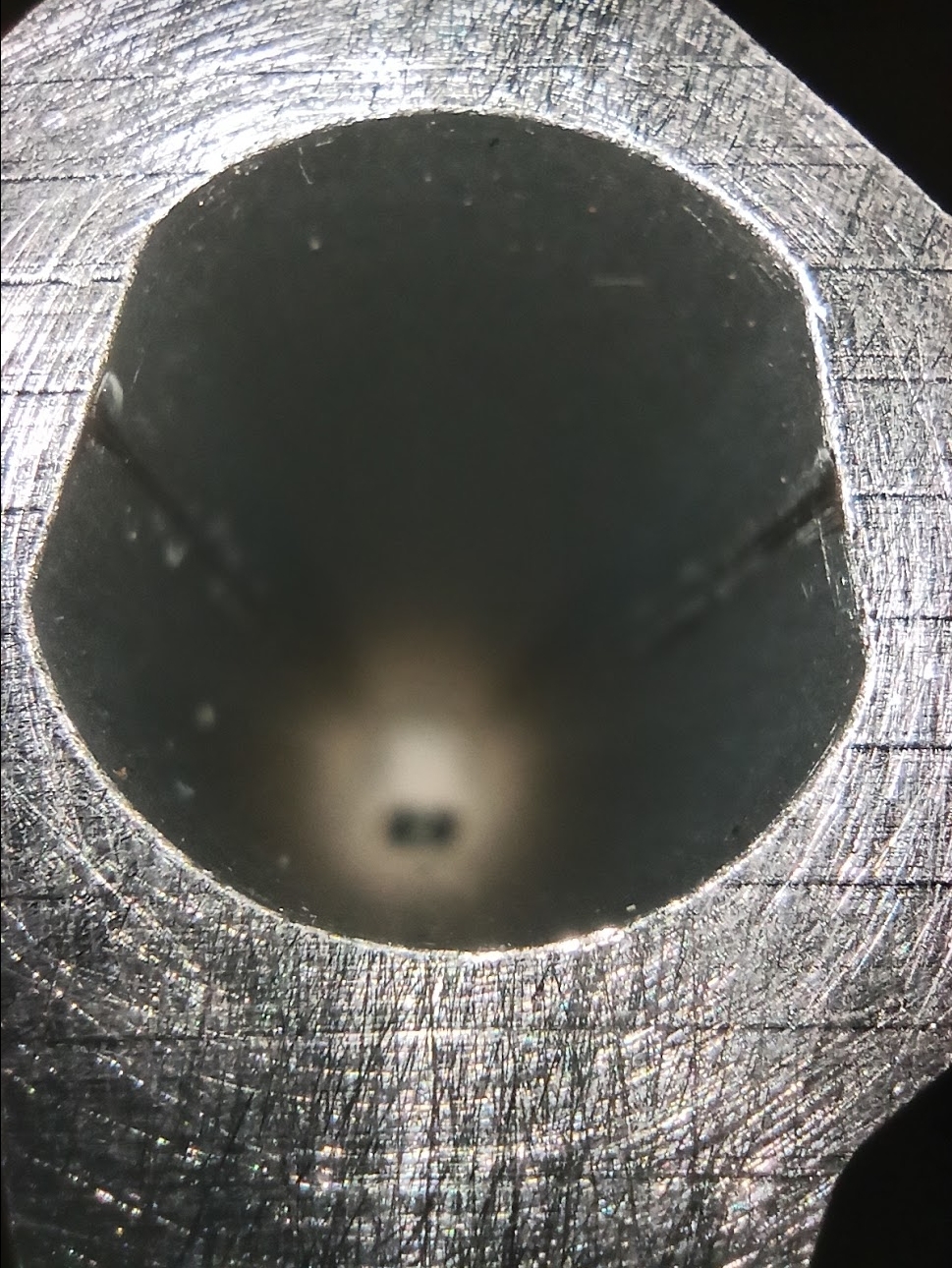

Using the sleeve I made, I do also get the USB to be more square to the wheel, this is clearly visible when holding a square to the stone and USB.

If we say that 83,2 (rough average of test #3) is truly square, you could potentially get the USB locked in at 84,2 (test result 4 in test #1) which would put the USB 1mm out of square at the end of the bar.

- I guess this doesn't really matter, since you would be truing the stone to the USB, but then the pesky deviation of 0,8mm comes into play.

Conclusion:

Make a sleeve or stop touching the universal support bar, when locking it in?

And yes, I did just move my machine to a more dedicated spot

I did some testing as suggested and my findings are somewhat surprising.

The measurements were taken from the top of the USB and down to the piece of solid bar steel. With both locking screws tightened.

- repeated test measurements with no altering of the USB, showed repeatability to within 0,05mm accuracy.

Results:

Pressing down on the threaded bar when locking it in, showed a max deviation of 0,8mm. (I didn't touch the nut, although I wrote it like that in my notes on my phone, it was done like in the Tormek manual/handbook)

Placing the USB freely before locking it in without touching it further, showed a max deviation of 0,15mm.

Using the sleeve and applying downwards pressure and spin to only the sleeve itself, while locking in the USB, showed a max deviation of 0,2mm.

I would say that 0,8mm deviation is too much for my liking, this corresponds with my observations truing the stone with the TT-50, where I noticed that from one pass to another, suddenly I would only be removing material from about half the stone, when taking away material in ½ increments of the micro adjust.

But I will also admit, that it isn't as bad as I thought it would be and I'm nowhere near experienced enough to really tell how much of an impact it might have on the final results.

Using the sleeve I made, I do also get the USB to be more square to the wheel, this is clearly visible when holding a square to the stone and USB.

If we say that 83,2 (rough average of test #3) is truly square, you could potentially get the USB locked in at 84,2 (test result 4 in test #1) which would put the USB 1mm out of square at the end of the bar.

- I guess this doesn't really matter, since you would be truing the stone to the USB, but then the pesky deviation of 0,8mm comes into play.

Conclusion:

Make a sleeve or stop touching the universal support bar, when locking it in?