- Welcome to Tormek Community Forum.

News:

Welcome to the Tormek Community. If you previously registered for the discussion board but had not made any posts, your membership may have been purged. Secure your membership in this community by joining in the conversations.

www.tormek.com

Recent posts

#1

Scissors Sharpening / Scissors sharpening difficult!...

Last post by troflog - Today at 02:16:51 PMI sharpen my knives on the Tormek with good results.

But scissors: No

My steps:

1. Use sharpie to set the angle

2. Grade my stone to 220

3. Sharpen with at least 10 passes for each blade

4. Feel for burr. If no burr then sharpen more

5. Use the separate blades and close method to debut

I tried to sharpen 5 scissors and got bad results on all. They got sharper but not close as the sharpness of new scissors.

All my scissors are cheap Ikea one. Some normal and some children sized.

Any tips? Have I over sharpened my scissors?

Do the quality of the scissors has any effect?

But scissors: No

My steps:

1. Use sharpie to set the angle

2. Grade my stone to 220

3. Sharpen with at least 10 passes for each blade

4. Feel for burr. If no burr then sharpen more

5. Use the separate blades and close method to debut

I tried to sharpen 5 scissors and got bad results on all. They got sharper but not close as the sharpness of new scissors.

All my scissors are cheap Ikea one. Some normal and some children sized.

Any tips? Have I over sharpened my scissors?

Do the quality of the scissors has any effect?

#2

General Tormek Questions / Re: US-103 & US-105 difference...

Last post by Ken S - Today at 02:03:10 PMRich is correct about the edge thickness of the two wheel sizes. However, the thickness of the two sizes at the indentation for the bore is almost identical. That is the reason why either size wheel will fit either size machine.

Please note that although this is possible does not mean that it is practical.

Ken

Please note that although this is possible does not mean that it is practical.

Ken

#3

Tormek T-1 and T-2 / T2 "202" video

Last post by Ken S - Today at 01:28:20 PMThe T2 Online Class is well done and informative. This video goes beyond it, adding the experience gained from more time in the field. It is located on the Tormek Culinary youtube channel and well worth watching. I recommend it not just for T2 users, but also for anyone who sharpens knives with a Tormek. Here is a link:

https://youtu.be/JFSg_eUYc10?si=B7Z5_LAHQPfh5YDc

Ken

https://youtu.be/JFSg_eUYc10?si=B7Z5_LAHQPfh5YDc

Ken

#4

General Tormek Questions / Re: US-103 & US-105 difference...

Last post by RichColvin - Today at 12:48:22 PMYes, the 250mm grindstone is 50mm wide, and the 200mm grindstone is 40mm wide.

#5

General Tormek Questions / Re: US-103 & US-105 difference...

Last post by cbwx34 - Today at 01:59:16 AMQuote from: RickKrung on Today at 01:52:00 AMQuote from: RichColvin on Yesterday at 09:24:47 PMBoth have legs which are 145mm long. The difference is in the top bar

- US-105 = 305mm

- US-103 = 295mm

As noted, the US-103 is 10mm shorter to accommodate the 200mm grindstone which is 10mm thinner than the 250mm grindstone.

10mm difference in length???

250mm - 200mm = 50mm

The width of the stone... 50mm vs 40mm

#6

General Tormek Questions / Re: US-103 & US-105 difference...

Last post by RickKrung - Today at 01:52:00 AMQuote from: RichColvin on Yesterday at 09:24:47 PMBoth have legs which are 145mm long. The difference is in the top bar

- US-105 = 305mm

- US-103 = 295mm

As noted, the US-103 is 10mm shorter to accommodate the 200mm grindstone which is 10mm thinner than the 250mm grindstone.

10mm difference in length???

250mm - 200mm = 50mm

#7

Knife Sharpening / Re: Simple Platform Jig

Last post by RichColvin - Yesterday at 09:33:14 PMPlease share the STL files.

#8

General Tormek Questions / Re: US-103 & US-105 difference...

Last post by RichColvin - Yesterday at 09:24:47 PMBoth have legs which are 145mm long. The difference is in the top bar

As noted, the US-103 is 10mm shorter to accommodate the 200mm grindstone which is 10mm thinner than the 250mm grindstone.

- US-105 = 305mm

- US-103 = 295mm

As noted, the US-103 is 10mm shorter to accommodate the 200mm grindstone which is 10mm thinner than the 250mm grindstone.

#9

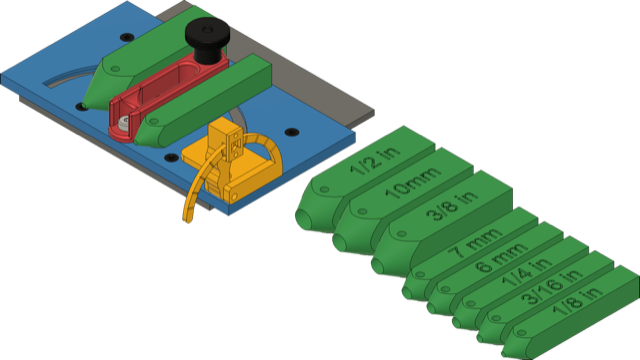

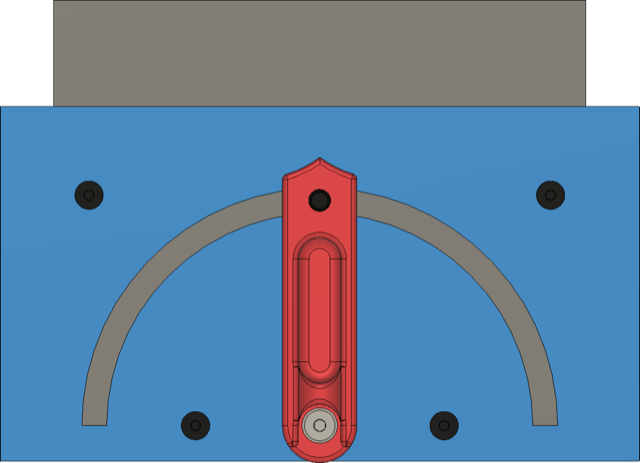

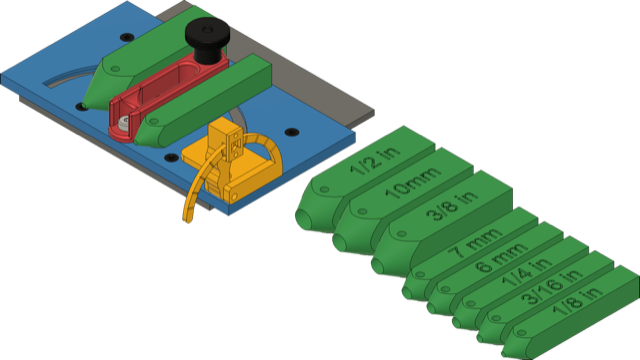

General Tormek Questions / Goniostat for the Tormek

Last post by RichColvin - Yesterday at 09:15:47 PMI am in the process of designing a goniostat for the Tormek, and am seeking feedback. This jig is designed for sharpening these types of tools:

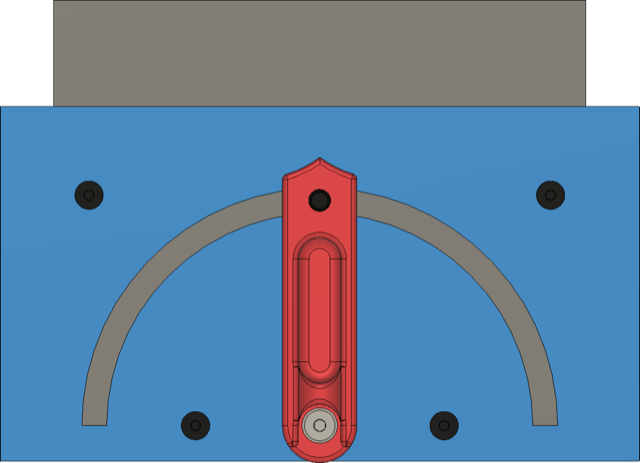

The picture below shows the parts I've designed so far.

The parts are:

The parts are:

- Single point cutting tools for small metal lathes.

- Engraving bits used in rotary cutters, especially as driven by a router type motor on a CNC machine, and

- Tools for ornamental turning, especially on rose engines.

- End mills

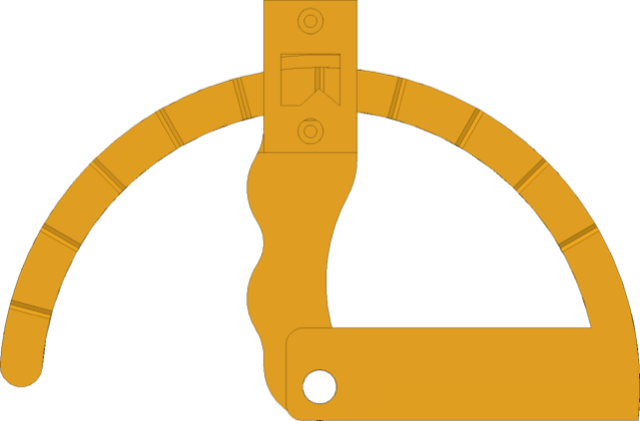

The picture below shows the parts I've designed so far.

- DBS-22 Plate (item #2, p/n 2350, shown in gray). This slides left / right on the base of the DBS-22.

- Goniostat Base Plate (blue). The final one will need some form of marking to show the angle for setting. The drawing below shows shows the tool fence with the pointer at the top and the locking knob removed. This angle would read 90°, and the fence can be rotated left or right as needed.

- Tool Fence (red) - used to set the angle for grinding the edge. The tool or tool holder would be held against this when sharpening.

The bolt coming up thru the Goniostat Base Plate is a T-Slot bolt from McMaster-Carr (p/n 92770A113). I had to turn the shoulder down a little so that it did not protrude too much above the surface of the Goniostat Base Plate. The area noted in red below is what was turned to the the same as the screw shaft.

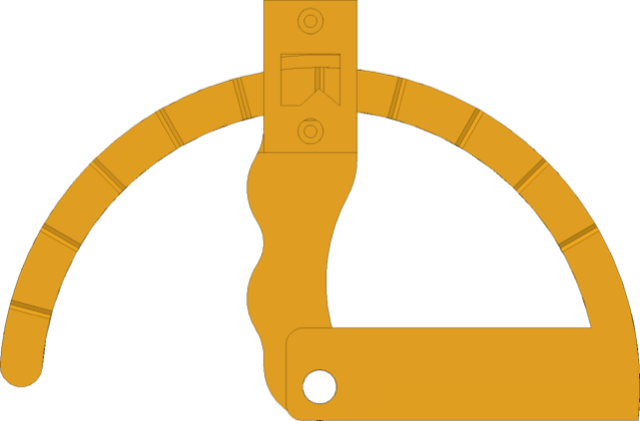

- Plate Angle Gauge (yellow) - used to set the angle of the plate (DBS-22 and Goniostat Base Plate) on the USB. This would also have indicator marks. They are simulated at 15° increments in the drawing below. There are no rollers on the design (like on the TTS-100). That would be an improvement which would be welcome.

- Round Tool Holders (green) - these are used to hold tools for sharpening which have round shafts. They have a 60° nose angle to allow the held tool to be ground up close. The hole in the top is for a 6mm set screw to hold the tool's shaft in place.

- The sizes shown on the right are the ones I will use. 3D printing the 8 of them will take a while on my 3D printer, which is pretty slow. There are two generic ones shown on the left. The left-most one is 25mm square and would be drilled for holding bigger tools. The other one is 15mm square and would be drilled for holding smaller tools.

#10

Knife Sharpening / Re: Simple Platform Jig

Last post by cbwx34 - Yesterday at 06:31:00 PMQuote from: tgbto on Yesterday at 08:55:42 AM...

A quick note on a design choise (which I am not sure is wise): the (grey) sliding platform is more or less self-locking inside the (blue) support. One has to flex it a bit by pressing down in the middle so it slides easily, then release it so it locks back in place, and the (red) back thumbscrew is just here to secure it in place and prevent bending. I might have to play with tolerances and/or add a bit of teflon or the like on the outer surfaces in contact with the support so it slides more smoothly but still locks without significant radial play..

...

Guess I don't see the need for a "sliding platform"... the Platform should accommodate just about any size knife without the need for this?